Types of Air-to-Air Heat Exchangers

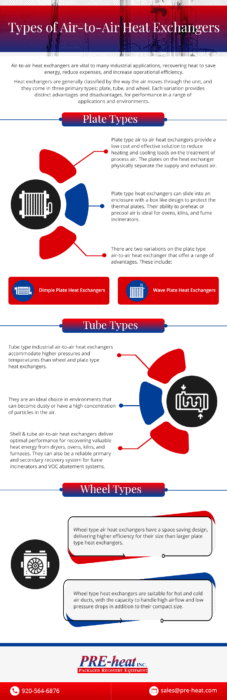

Leave a CommentA variety of industries rely on air-to-air heat exchangers to collect heat energy lost during heating applications. They are vital to many industrial applications, recovering heat to save energy, reduce expenses, and increase operational efficiency. Heat exchangers are generally classified by the way the air moves through the unit, and they come in three primary types: plate, tube, and wheel. Each variation provides distinct advantages and disadvantages, for performance in a range of applications and environments.

We will discuss the types of air-to-air heat exchangers, their benefits, and applications to help you select the ideal heat exchanger for your application.

Plate Types

Plate type air-to-air heat exchangers provide a low-cost and effective solution to reduce heating and cooling loads on the treatment of process air. The plates on the heat exchanger physically separate the supply and exhaust air, with the supply air passing on one side and the exhaust air passing on the other side. The exhaust air is used to preheat or precool incoming supply air without mixing the air streams.

Plate type heat exchangers can slide into an enclosure with a box-like design to protect the thermal plates. Their ability to preheat or precool air is ideal for ovens, kilns, and fume incinerators.

There are two variations on the plate type air-to-air heat exchanger that offer a range of advantages.

These include:

- Dimple plate heat exchangers. Dimple plate heat exchangers have enhanced versatility and ruggedness for heavy-duty applications. The dimples on the plate allow the heat exchanger to handle low pressure drop and improve turbulence. The flat plates and the consistent dimple patterns allow for simple cleaning and maintenance.

- Wave plate heat exchangers. Wave plate heat exchangers are an all-welded metal heat exchanger that combines in-line dimple patterns with a wave pattern on the plates. This combination allows the heat exchanger to deliver higher turbulence and structural integrity while maintaining low pressure drop. They also feature heavy-duty plates that are easy to clean.

Plate type industrial air-to-air heat exchangers can be made to a range of specifications with various thicknesses, spaces, and sizes. When plate type heat exchangers do not deliver adequate performance, tube type air-to-air heat exchangers may offer a suitable solution.

Tube Types

Tube type industrial air-to-air heat exchangers accommodate higher pressures and temperatures than wheel and plate type heat exchangers. They are also an ideal choice in environments that can become dusty or have a high concentration of particles in the air.

Shell & tube air-to-air heat exchangers deliver optimal performance for recovering valuable heat energy from dryers, ovens, kilns, and furnaces. They can also be a reliable primary and secondary recovery system for fume incinerators and VOC abatement systems.

Shell & tube air-to-air heat exchangers have various patterns on the tubes, including rotated squares, rotated triangles, squares, or triangular patterns. Further variations include multiple tube side passes and shell side passes to increase performance and meet size specifications.

Wheel Types

Wheel type air heat exchangers have a space-saving design, delivering higher efficiency for their size than larger plate type heat exchangers. The rotating wheel’s extended surface makes contact with heat energy from the exhaust and transfers it to the incoming fresh air while each stream remains separate. Wheel type heat exchangers are suitable for hot and cold air ducts, with the capacity to handle high airflow and low-pressure drops in addition to their compact size.

Industrial Air-to-Air Heat Exchangers From PRE-heat

Air-to-air heat exchangers come in several types to suit a range of industrial applications, offering an efficient way to recover heat in various industries. At PRE-Heat Inc., we carry plate type and tube type air-to-air heat exchangers.

We have over 40 years of experience in designing and building industrial air-to-air heat exchangers, offering innovative, top-quality solutions that meet your specific needs. For more information, or to get started on your custom solution, request a quote today.

Common Industrial Applications for Air-to-Air Heat Exchangers

Leave a CommentMany industrial processes create heated air as some type of exhaust or byproduct. Typically, this heated air gets vented outside into the environment. Air-to-air heat exchangers offer a way to capture this exhaust air and reuse it at other points in the application process. Exhaust air can preheat outside fresh air that needs to be used for certain tasks, such as curing sealants or pre-heating ovens, by running the exhaust air through tubes. When the outside air passes over the tubes, the fresh air heats up without the risk of contamination by the exhaust air.

Another type of heat exchanger, called an air-to-air plate exchanger, allows an industrial facility to harvest the potential energy found in exhaust air and provide air pollution control. The heat exchanger attaches to incinerators, kilns, and ovens. The exhausted air and clean air pass over the plates without encountering each other. The plate collects the heat from the exhaust air and passes into the clean intake air, while the cooler exhausted air condenses onto the walls and the plates. Cleaner exhaust air is then vented into the environment.

Applications That Rely on Air-to-Air Heat Exchangers

Automotive and air pollution control rely heavily on air-to-air heat exchangers to recover wasted heat energy and direct it toward other processes. Air-to-air heat exchangers allow these two industries to lower their energy costs and condition fresh outdoor air use in their applications.

Automotive Industry

The automotive industry uses heat exchangers to recover heat from incinerators for use in dryers. The stainless steel construction of the heat exchanger allows it to withstand any particulates and corrosive contaminants that may collect in the exhaust flow. Because the inflow of cooler air becomes heated when passing through the heat transfer equipment, the preheated air can then be directed to e-coat and paint curing ovens. Pre-heating the air allows automotive manufacturers to spend less on outside energy sources to bring the oven temperatures up to required temperature ranges.

Air Pollution Control Systems

Large amounts of energy are used to incinerate harmful VOCs or cool compounds before a baghouse. Those incinerators use a lot of fuel to keep the burners running at the required temperature. The use of a heat exchanger can reduce this cost by using the hot air to heat up the VOC air before the burner. Or vise versa, the heat exchanger can be used to cool air streams with volatile compounds before a baghouse to be captured.

Other Industrial Heat Exchanger Applications

Many other industries also use air-to-air heat exchangers in their processes. The heat exchanger may be used to pre-cool air, pre-heat air, start curing or drying processes, and provide secondary air/heat recovery.

Industries and applications that rely on air-to-air heat exchange capabilities may include, but are not limited to:

- Bag house precooler

- Furnace

- Plastics industry

- Solvent recovery systems

- Bakery ovens

- Power generation

- Printing industry

- Mineral industry

- Tape manufacturing

- Bottling plant

- Plant machine hood exhaust

- Textile industry

- Make up air/heat systems

Air-to-Air Heat Exchangers from PRE-Heat

Air-to-air heat exchangers play a critical role in reducing energy costs and minimizing industrial air pollution. At PRE-Heat, Inc., we offer heat exchangers for a variety of industrial applications.

For assistance identifying the right air-to-air heat exchange solution for your needs, please don’t hesitate to contact us or request a quote today.