Process heating is critical to a variety of industrial processes, from food manufacturing to pollution control systems. Indirect-fired heaters heat air for applications where direct contact with combustion products is detrimental to the process or product. Unlike direct heaters, indirect-fired heaters heat process air without contaminating the product with combustion products.

Like a boiler, indirect-fire air heaters create energy by combusting liquid or gaseous fuel in a combustion chamber. The resulting combustion products heat the process air to the desired temperature but are kept separate from the process air by an air-to-air heat exchanger.

Purpose of Indirect-Fired Air Heaters

Single Hot Pass Design

This indirect-fired heater design uses a burner and high-temperature chamber to heat process air as it passes over the heater. Heat is generated by a burner firing into a specially designed high-temperature chamber, which is engineered to radiate. The process air is pulled, or blown, over the heater and heated to the desired temperature. This system is ideal for recirculated air processes like paint booths and smokers. This type of indirect-fired heater is approximately 60-70% efficient.

Multiple Hot Pass Design

These indirect-fired heaters consist of a burner, a combustion chamber, an air-to-air heat exchanger, and high-temperature fans. In this type of heater, the high-temperature fans pull the hot products of combustion, produced by the burner, through an air-to-air heat exchanger heating the process air passing through the other side of the heat exchanger. The hot gasses then reenter the system to create a continuous heating loop. As the process air is separated from the hot gases by the heat exchanger, they are free from products of combustion providing hot, clean air to the process.

This design can heat high volumes of air with more than 90% efficiency. The heater’s efficiency can be further enhanced by installing an air-to-air heat exchanger in the process exhaust system, so clean air can be heated before it enters the main heating chamber. This type of heater is ideal for use in food-grade spray dryers and mineral drying applications.

Applications of Indirect-Fired Air Heaters

Indirect-fired heaters are valued for their ability to rapidly and efficiently heat process air without contaminating processes through direct contact or the diffusion of combustion byproducts into the process. Applications that benefit from indirect fire heaters include:

- Food Manufacturing: Perfect for food-grade applications such as spray dryers for dairy products, produce, and other food products.

- Pharmaceuticals: Incorporated into pharmaceutical manufacturing for heating and drying products.

- Chemical Manufacturing: Used to heat and dry chemicals while preventing the intrusion of contaminants from combustion processes.

- Automotive Paint and Detailing: Used in recirculating systems for painting, lining, coating, and detailing.

- Pollution Control Systems: Heats downstream exhaust to eliminate pollutants without adding additional contaminants to the stream.

- Iron Industry: Used to heat pellets and other products without introducing contaminants that can cause unwanted chemical impurities.

- Printing Presses: Used to quickly and efficiently dry ink on paper products, labels, and other high-volume products.

- Heating Industrial and Commercial Buildings: Ensures clean heated air is circulated in commercial and industrial facilities for a healthier work environment.

Direct vs. Indirect Air Heaters

While direct-air heating is the most common method of industrial heating, it does introduce products of combustion into the process air stream. In applications where the product cannot be exposed to the CO2, CO, NOx, H2O, SOx, or particulate produced during the combustion process, an indirect air heater is the only option.

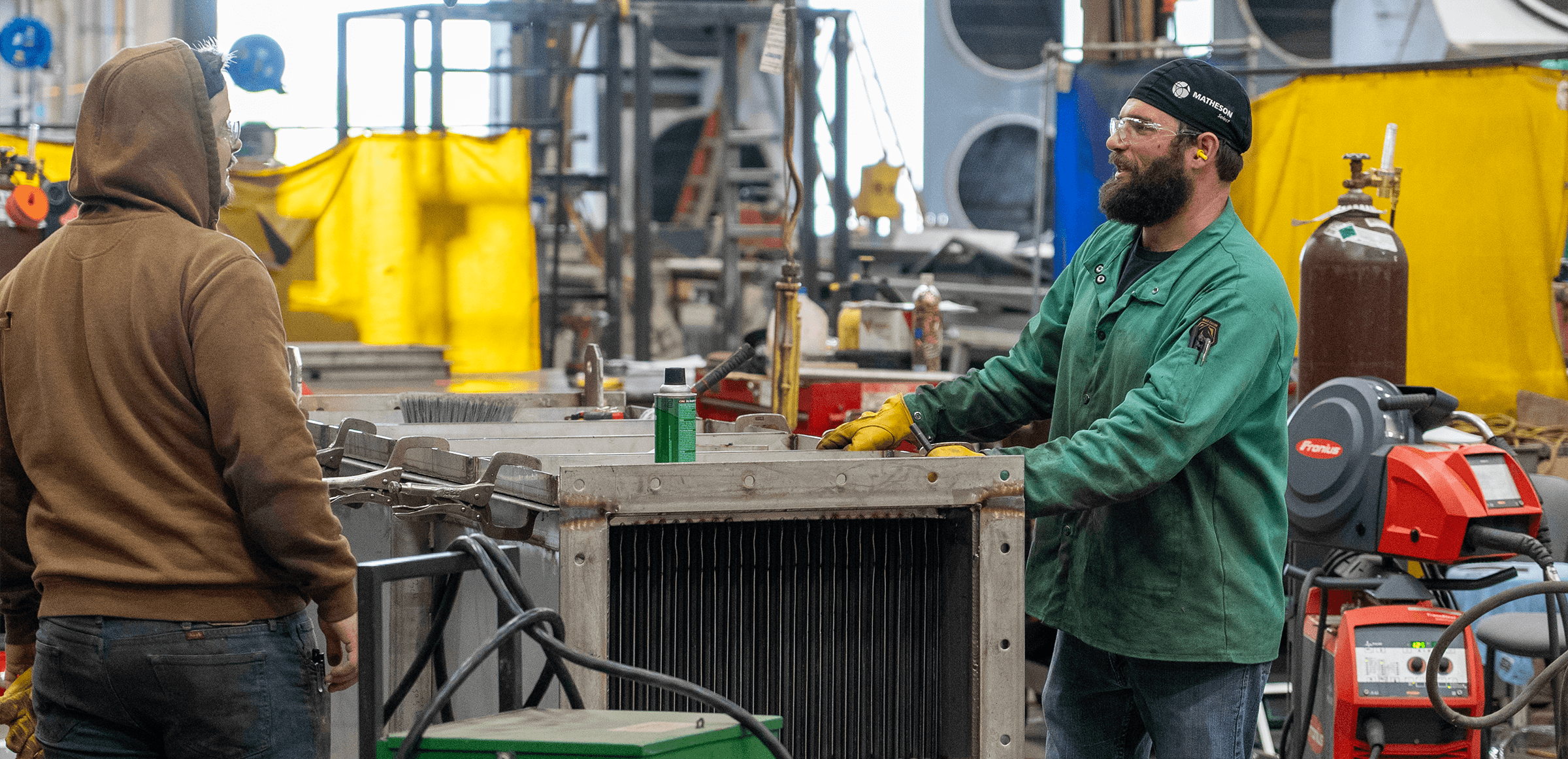

Cutting-Edge Air-to-Air Heating Solutions by PRE-heat, Inc.

PRE-heat, Inc., is a leading provider of air-to-air indirect heating solutions for our customers in commercial and industrial sectors. As experienced fired-heater manufacturers, we leverage our expertise to create economical, efficient, and effective solutions to meet a variety of process heating needs. To learn more about our extensive selection of indirect-fired heaters and custom heating solutions, contact our experts today or request a quote.