In the industrial world, it is extremely common for manufacturing processes to create some type of exhaust or byproduct. The byproduct is commonly released into the environment. This heated air is one of the most wasted resources in the manufacturing world. With air-to-air heat exchangers, this heated air is recaptured and put back into use in the manufacturing process. This blog will look at four of the benefits of air-to-air heat exchangers and the reuse of heat.

Efficiency

One of the main benefits associated with recuperating heat is improved efficiency. Creating large amounts of heat takes time and energy, and maintaining this heat takes even more time and energy. With air-to-air heat exchangers, heat can be recycled back into the system, improving energy efficiency, manufacturing efficiency, and pollution control efficiency. With new energy efficiency standards coming to manufacturing industries, air-to-air heat exchangers provide the perfect solution.

Air Pollution Control

Air-to-air heat exchangers can help mitigate the issues related to managing volatile organic compounds (VOCs) in industries where production processes generate harmful VOCs as a byproduct. It’s important to note that heat exchangers do not destroy or incinerate VOCs but help to control these compounds. By using a heat exchanger, a manufacturer can control the temperature of contaminated air. This can be done in conjunction with a regenerative thermal oxidizer or a combustion chamber. The heat exchanger in these instances can pre-heat the contaminated air before the VOCs are destroyed in the connected system.

Money Savings

The main money savings of air-to-air heat exchangers come from their energy efficiency, which requires less investment than systems without them. Manufacturers also see substantial savings from a heat exchanger due to its high return on investment (ROI) in the long term. While the initial investment for air-to-air heat exchangers may be high, they require very minimal maintenance and last for an extremely long time. This means that using an air-to-air heat exchanger will passively recoup the initial investment in a standard manufacturing process. Comparatively, other forms of heat exchangers, like liquid-to-liquid or gas-to-liquid, require far more maintenance and go through much more wear and tear, shortening the lifespan of the heat exchanger.

Versatility

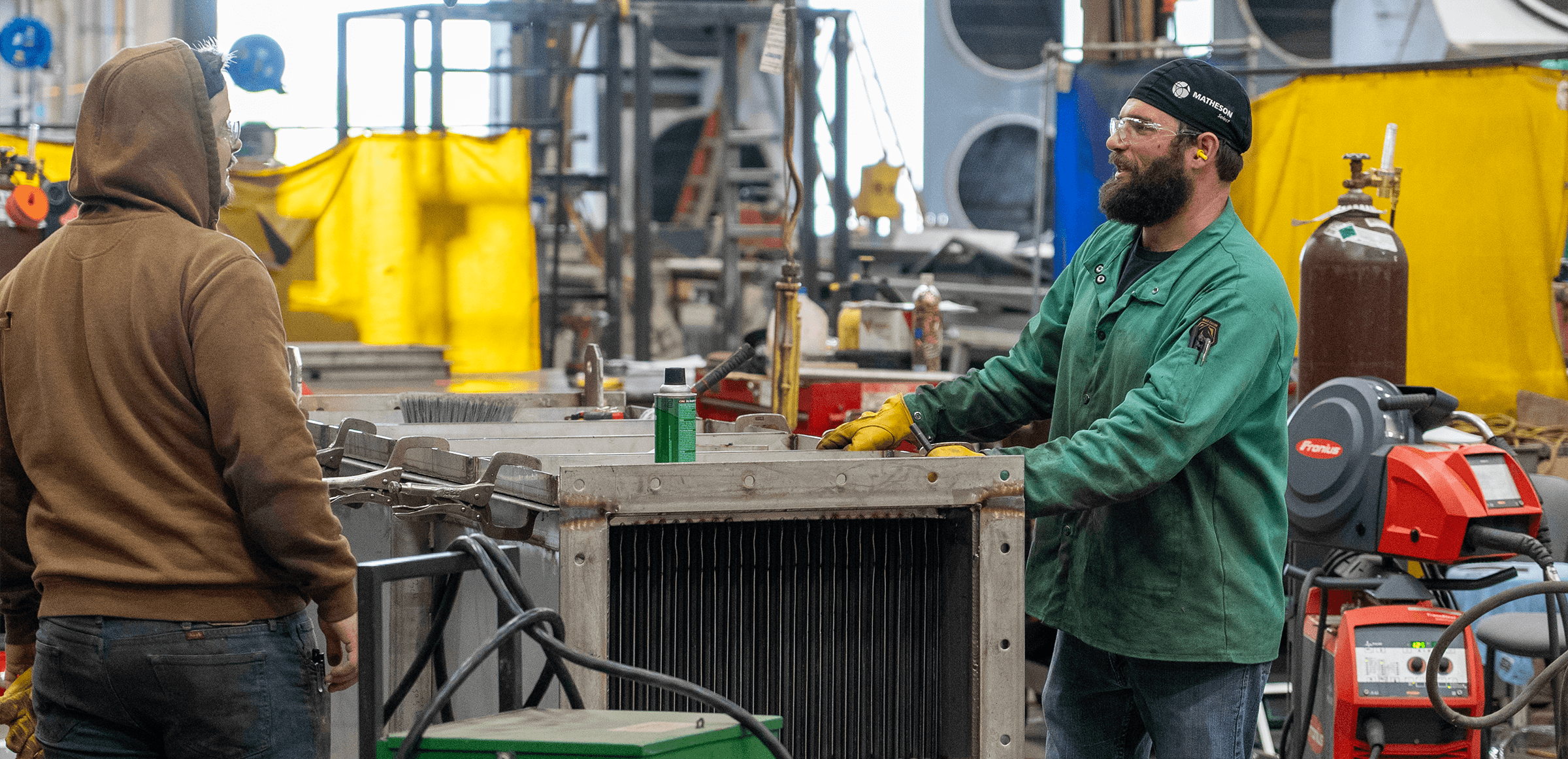

Air-to-air heat exchangers are extremely versatile in both application and structure. They can be retrofitted to existing systems to minimize changes to existing manufacturing processes. We can achieve this through custom fabrication methods, which we can also utilize to replace old and inefficient heat exchangers.

Air-to-air heat exchangers can be used in numerous diverse industries, such as automotive, bottling plants, grain dryers, industrial heating/cooling, oil refineries, food and beverage, asphalt production, and many more. It is very unlikely that an industry can’t benefit from an air-to-air heat exchanger.

A Leader in the Industry

PRE-heat is the leader in the heat exchanger industry with its air-to-air heat recovery equipment. PRE-heat serves industries with shell and tube, wave plate, cooling towers, and specialty dimple plate heat exchangers. With PRE-heat, you can save money and stay up to date with the latest energy efficiency requirements.