Pros and Cons of Air-to-Air Heat Exchangers

Leave a CommentAir-to-air heat exchangers are common in a variety of diverse industries for effectively carrying out heat transfer and recovering wasted heat from exhaust air for use in other equipment. Managing thermal energy is particularly important for technological, power, and other utility installations, though it has specific benefits and drawbacks to consider for any application. Before integrating an air-to-air heat exchanger into your systems, learn more about this equipment and its ideal uses.

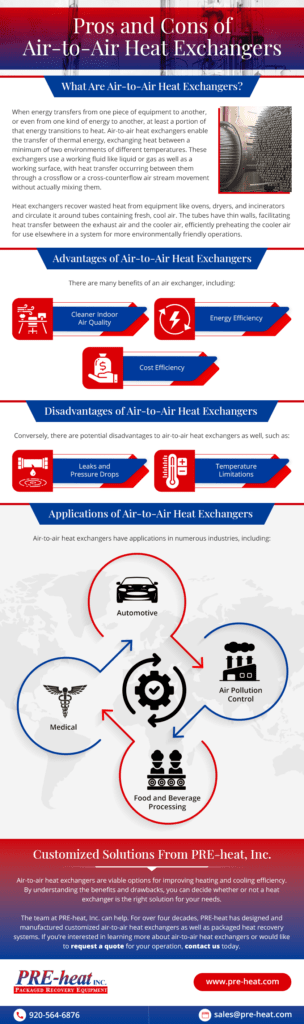

What Are Air-to-Air Heat Exchangers?

When energy transfers from one piece of equipment to another, or even from one kind of energy to another, at least a portion of that energy transitions to heat. Air-to-air heat exchangers enable the transfer of thermal energy, exchanging heat between a minimum of two environments of different temperatures. These exchangers use a working fluid like liquid or gas as well as a working surface, with heat transfer occurring between them through a crossflow or a cross-counterflow air stream movement without actually mixing them.

Heat exchangers recover wasted heat from equipment like ovens, dryers, and incinerators and circulate it around tubes containing fresh, cool air. The tubes have thin walls, facilitating heat transfer between the exhaust air and the cooler air, efficiently preheating the cooler air for use elsewhere in a system for more environmentally friendly operations.

Advantages of Air-to-Air Heat Exchangers

There are many benefits of an air exchanger, including:

- Cleaner indoor air quality. Regarding ventilation, the air-to-air heat exchanger core uses high-performance filters to ensure healthy, breathable air and pleasant indoor temperatures. In addition to removing pollutants and excess moisture from the air, heat exchangers also effectively eliminate foul smells.

- Energy efficiency. Air-to-air heat exchangers recover energy by capitalizing on exhaust airstreams, wasted or latent heat, and passive cooling, lowering your operation’s carbon footprint. As these heat exchangers do not utilize any power, that equates to lower energy consumption. Also, it makes them ideal for locations in which electricity inaccessible..

- Cost efficiency. As compared to other cooling equipment like air conditioners, heat exchangers are more cost-efficient for thermal management in an enclosed space. Their only moving components are their circulation fans, and this leads to energy bill savings.

Disadvantages of Air-to-Air Heat Exchangers

Conversely, there are potential disadvantages to air-to-air heat exchangers as well, such as:

- Leaks and pressure drops. When leaks do develop, allowing two airstreams to mix through a hole in the exchanger, they can be hard to fix, often requiring a full deconstruction. Similarly, when system pressure drops off within a plate heat exchanger, technicians typically have to inspect each plate individually to locate the source of the problem.

- Temperature limitations. Air-to-air heat exchangers are only capable of functioning in environments where the external air temperature is less than that of the system’s internal maximum operational temperature. Also, they cannot effectively cool spaces that are already overheated. This can be remedied, however, by using them in combination with other machinery.

Applications of Air-to-Air Heat Exchangers

Air-to-air heat exchangers have applications in numerous industries, including:

- Automotive. Corrosion-resistant stainless steel heat exchangers can handle exhaust flow from automotive applications, despite its contaminants. They have applications in incinerator heat recovery for dryer usage, as well as preheated air for ovens that cure paint or other coatings.

- Air pollution control. Using a heat exchanger can save energy in an air pollution control system by preheating air streams containing volatile organic compounds (VOCs) or precooling air before its introduction into a baghouse. This cuts down on the amount of fuel that incinerators would otherwise use to maintain specific temperatures.

- Food and beverage processing. Safety is always a priority in the food and beverage sector. Heat exchangers provide greater control over temperature than other thermal management techniques, facilitating sanitizing. Also, they keep refrigerants like freon separate from consumable goods to safely cool equipment and control panels during manufacturing.

- Medical. Medical equipment can generate a fair amount of heat in sealed areas. To solve this, the industry can integrate heat exchangers into healthcare equipment to promote operational efficiency and accuracy, as well as extend the life span of medical devices.

Customized Solutions From PRE-heat, Inc.

Air-to-air heat exchangers are viable options for improving heating and cooling efficiency. By understanding the benefits and drawbacks, you can decide whether or not a heat exchanger is the right solution for your needs.

The team at PRE-heat, Inc. can help. For over four decades, PRE-heat has designed and manufactured customized air-to-air heat exchangers as well as packaged heat recovery systems. If you’re interested in learning more about air-to-air heat exchangers or would like to request a quote for your operation, contact us today.