A Look at Heat Recovery Systems

Leave a CommentEvery facility loses heat to the atmosphere. In industrial settings, this loss is a significant source of wasted energy and money. Recovering even a portion of lost heat allows companies to improve their energy efficiency, save money, and reduce their carbon footprint without altering existing workflows.

In this post, we will cover topics such as important qualities of heat recovery equipment and how to select the right one for your situation and application, including indirect heaters and heat exchangers.

What Is a Heat Recovery System?

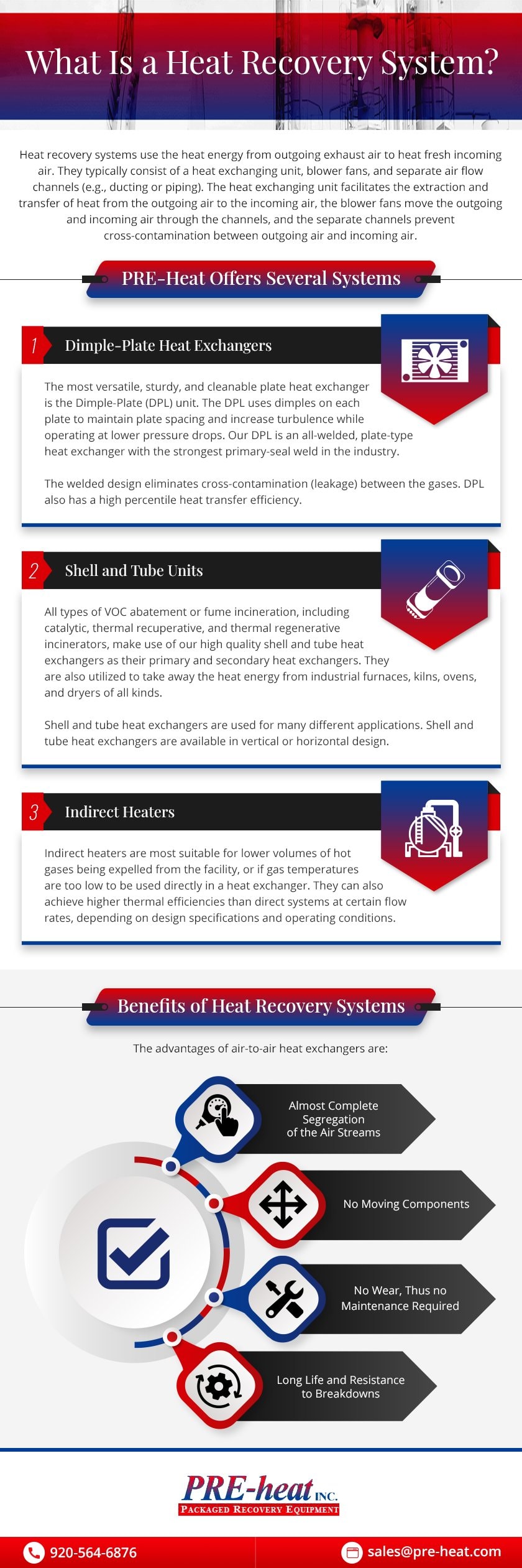

Heat recovery systems use the heat energy from outgoing exhaust air to heat fresh incoming air. They typically consist of a heat exchanging unit, blower fans, and separate air flow channels (e.g., ducting or piping). The heat exchanging unit facilitates the extraction and transfer of heat from the outgoing air to the incoming air, the blower fans move the outgoing and incoming air through the channels, and the separate channels prevent cross-contamination between outgoing air and incoming air.

PRE-Heat Offers Several Systems

Dimple-Plate Heat Exchangers

The most versatile, sturdy, and cleanable plate heat exchanger is the Dimple-Plate (DPL) unit. The DPL uses dimples on each plate to maintain plate spacing and increase turbulence while operating at lower pressure drops. Our DPL is an all-welded, plate-type heat exchanger with the strongest primary-seal weld in the industry.

The welded design eliminates cross contamination (leakage) between the gases. DPL also has a high percentile heat transfer efficiency. Variable plate thickness, spacing, and size are chosen to satisfy system needs while further optimizing performance and cost. Cleaning and inspecting accessible ports are possible.

Shell and Tube Units

All types of VOC abatement or fume incineration, including catalytic, thermal recuperative, and thermal regenerative incinerators, make use of our high quality shell and tube heat exchangers as their primary and secondary heat exchangers. They are also utilized to take away the heat energy from industrial furnaces, kilns, ovens, and dryers of all kinds.

Shell and tube heat exchangers are used for many different applications. They can be placed in the exhaust of the object to be heated, or they can also be placed in the input of the object to be cooled. Shell and tube heat exchangers are available in vertical or horizontal design. When the exhaust air is very dirty, shell and tube heat exchangers are recommended because they don’t need frequent cleaning.

Indirect Heaters

Indirect heaters are most suitable for lower volumes of hot gases being expelled from the facility, or if gas temperatures are too low to be used directly in a heat exchanger. They can also achieve higher thermal efficiencies than direct systems at certain flow rates, depending on design specifications and operating conditions.

Benefits of Heat Recovery Systems

The ever-increasing operating expenses of heating, air conditioning, and ventilation can be significantly reduced by heat recovery from exhaust air.

The advantages of air-to-air heat exchangers are:

- Almost complete segregation of the air streams

- No moving components

- No wear, thus no maintenance required

- Long life and resistance to breakdowns

Who Needs a Heat Recovery System?

Heat recovery equipment is an integral part of the heating, ventilation, and air conditioning systems in buildings. As structures are being built for energy efficiency, they have become more tightly sealed so that natural pollutants cannot escape these structures over time. These natural pollutants can lead to poor air quality inside your building if not expelled from time to time through installing well thought-out equipment such as the heat recovery system or indirect heater.

Heat recovery systems are important in any industry that uses (or needs) heating, ventilation, or air conditioning systems, such as in car manufacturing and food and beverage processing. The purpose of the heat recovery system is thus two-fold: first, it ensures those natural pollutants can leave the structure, and secondly, it allows companies to achieve their goal of improved energy efficiency as well as a reduced carbon footprint by recovering lost excesses.

Heat loss represents a significant source of wasted energy and money in industrial settings. Recovering even a portion of lost heat allows companies to improve their energy efficiency, save money, and reduce their carbon footprint, all without altering existing workflows.

The end goal of the heat recovery system is to provide the most efficient use of energy possible. When designing a heat recovery system, it’s important to establish these goals up front, so that the design properly reflects what is required. The end-state of a heat recovery system is ultimately determined by the building’s final use and what the people who will live or work in it require. When designing the heat recovery system, be sure to consider these variables.

How We Can Help

Do you need help with designing an indirect heater, heat recovery system, or other industrial heating equipment? Or do you have questions about how to correctly size/configure your components so that they work together seamlessly for maximum energy savings and efficiency? PRE-heat is on hand to answer all of your questions!

Don’t forget to grab your free eBook to gain access to expert information that has helped prior clients choose the perfect heat recovery system for their industry.

The Top Uses for Indirect-Fired Air Heaters

Leave a CommentProcess heating is a critical aspect of a variety of industrial processes, from food manufacturing to pollution control systems. Indirect-fired heaters are used to heat air for applications where direct contact with products of combustion is detrimental to the process or product. Unlike direct heaters, indirect-fired heaters heat process air without contaminating the product with products of combustion.

Similar to a boiler, indirect-fire air heaters create energy by combusting liquid or gaseous fuel in a combustion chamber, the resulting products of combustion heat the process air to the desired temperature but are kept separate from the process air by an air-to-air heat exchanger.

Purpose of Indirect-Fired Air Heaters

Indirect-air heaters are engineered to heat process air without contaminating the process environment. This can be achieved in two ways:

Single Hot Pass Design

This indirect-fired heater design uses a burner and high-temperature chamber to heat process air as it passes over the heater. Heat is generated by a burner firing into a specially designed high-temperature chamber, which is engineered to radiate. The process air is pulled, or blown, over the heater and heated to the desired temperature. This system is ideal for recirculated air processes like paint booths and smokers. This type of indirect-fired heater is approximately 60-70% efficient.

Multiple Hot Pass Design

These indirect-fired heaters consist of a burner, combustion chamber, an air-to-air heat exchanger and high-temperature fans. In this type of heater, the high-temperature fans pull the hot products of combustion, produced by the burner, through an air-to-air heat exchanger heating the process air passing through the other side of the heat exchanger. The hot gasses then reenter the system to create a continuous heating loop. As the process air is separated from the hot gases by the heat exchanger they are free from products of combustion providing hot, clean air to the process.

This design can heat high volumes of air with more than 90% efficiency. The heater’s efficiency can be further enhanced by installing an air-to-air heat exchanger in the process exhaust system, so clean air can be heated before it enters the main heating chamber. This type of heater is ideal for use in food-grade spray dryers and mineral drying applications.

Applications of Indirect-Fired Air Heaters

Indirect-fired heaters are valued for their ability to rapidly and efficiently heat process air without contaminating processes through direct contact or the diffusion of combustion byproducts into the process. Applications that benefit from indirect fire heaters include:

- Food Manufacturing: Perfect for food-grade applications such as spray dryers for dairy products, produce, and other food products.

- Pharmaceuticals: Incorporated into pharmaceutical manufacturing for heating and drying products.

- Chemical Manufacturing: Used to heat and dry chemicals while preventing the intrusion of contaminants from combustion processes.

- Automotive Paint and Detailing: Used in recirculating systems for painting, lining, coating, and detailing.

- Pollution Control Systems: Heats downstream exhaust to eliminate pollutants without adding additional contaminants to the stream.

- Iron Industry: Used to heat pellets and other products without introducing contaminants that can cause unwanted chemical impurities.

- Printing Presses: Used to quickly and efficiently dry ink on paper products, labels, and other high-volume products.

- Heating Industrial and Commercial Buildings: Ensures clean heated air is circulated in commercial and industrial facilities for a healthier work environment.

Direct vs. Indirect Air Heaters

While direct-air heating is the most common method of industrial heating, it does introduce products of combustion into the process air stream. In applications where the product cannot be exposed to the CO2, CO, NOx, H2O, SOx, or particulate produced during the combustion process, an indirect air heater is the only option.

Cutting-Edge Air-to-Air Heating Solutions by PRE-heat, Inc.

PRE-heat, Inc., is a leading provider of air-to-air indirect heating solutions for our customers in commercial and industrial sectors. As experienced fired-heater manufacturers, we leverage our expertise to create economical, efficient, and effective solutions to meet a variety of process heating needs. To learn more about our extensive selection of indirect-fired heaters and custom heating solutions, contact our experts today or request a quote.